Fiber reinforcement for carbon rims

✓ Are you a manufacturer of carbon rims for cars, trucks, commercial vehicles, agricultural machinery, tuning parts or motorsport?

✓ Do you need a lightweight and very strong reinforcement for further processing in your carbon rims using thermoset processes?

✓ Are you looking for a supplier or manufacturer who will work with you to develop a customized reinforcement for your carbon rims and produce it for you at a reasonable price?

Then read on!

Tailor-made alignment of the fibers along the load lines and points of your carbon rims

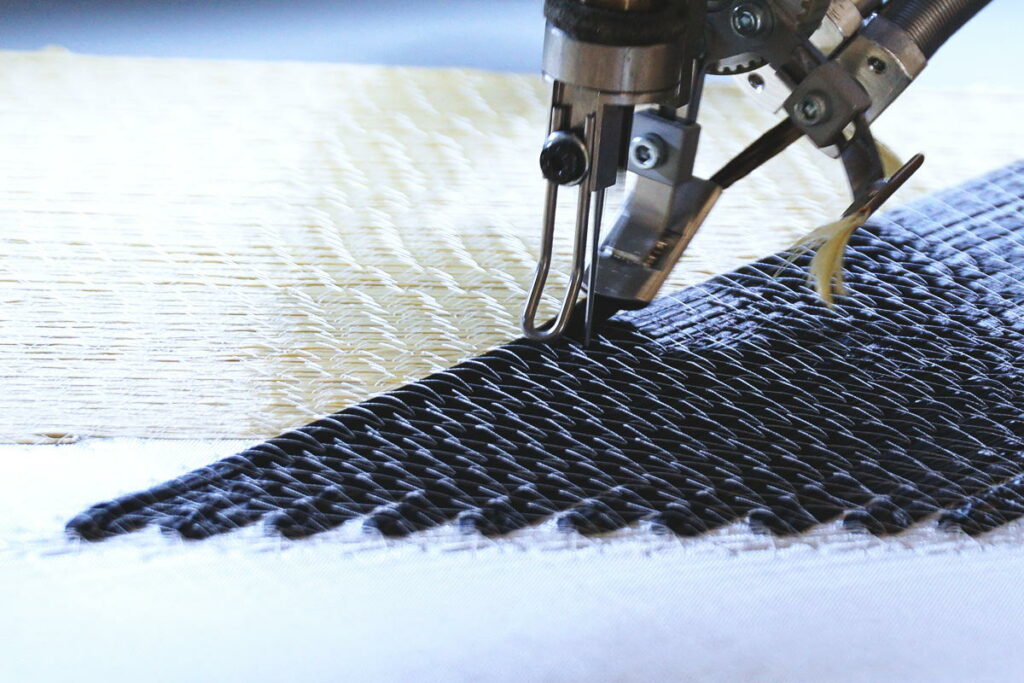

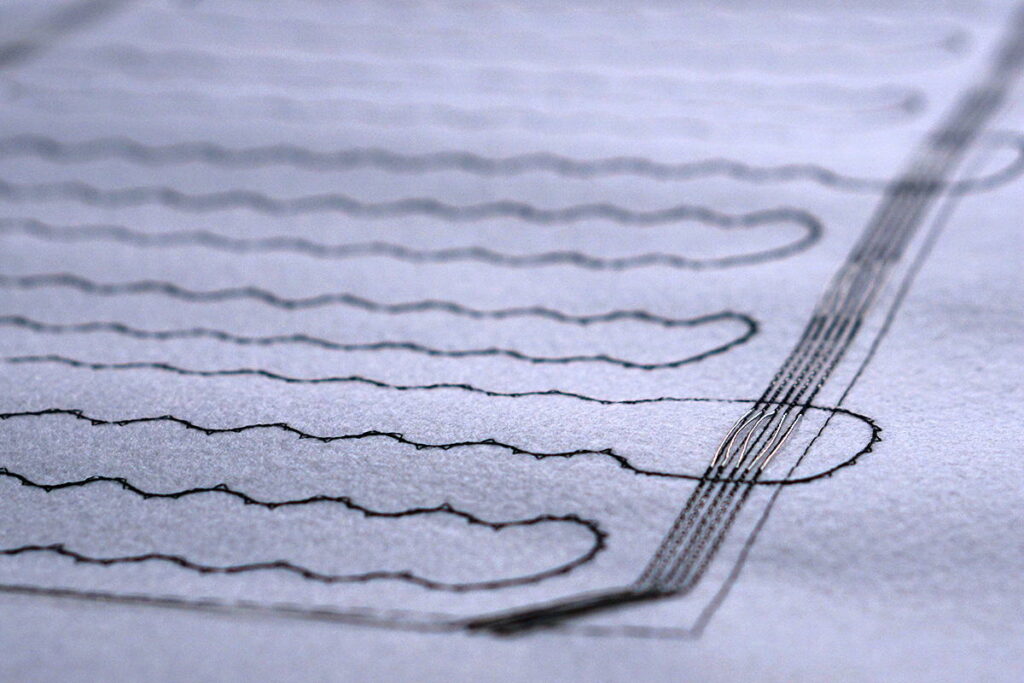

Our innovative TFP process places carbon fibres in a targeted and precise manner to optimize the structure and strength of your end product.

In the case of carbon rims, TFP enables a customized alignment of the fibres along the load lines and points of the rim. This leads to improved structural integrity and performance of the rim, especially under extreme conditions such as high speeds or dynamic driving maneuvers.

We manufacture fiber preforms for the B2B market with a high level of reproducibility. You can process the semi-finished products we manufacture into your innovative products using thermoset or thermoplastic processes.

Carbon fiber rims offer a number of advantages and are not only popular with tuners and car enthusiasts. They are also becoming increasingly popular in motorsport.

You too can benefit from the advantages of the TFP process!

Car & Motorsport

Motorsport requires top performance from man and material. Carbon rims with tailor-made fiber reinforcement along the load lines and load points combine maximum performance with low weight.

Your customers benefit from:

- Weight reduction for faster vehicle response and improved vehicle dynamics

- High stiffness for optimum control and performance

- Customized design for racing teams and vehicle owners

Trucks, commercial vehicles & agricultural machinery

Demanding environments and heavy loads place high demands on carbon rims.

- Weight reduction for improved fuel efficiency and higher payload capacity

- High strength for high loads and stresses in commercial vehicles

- Improved vehicle dynamics - traction, stability and maneuverability - for demanding off-road conditions or transporting heavy loads

Tuning parts

Advantages of carbon rims with TFP process

- Weight reduction: Thanks to the targeted placement of carbon fibers, carbon rims with TFP can be considerably lighter than conventional steel or aluminum rims. These weight savings help to improve vehicle performance and reduce fuel consumption and emissions.

- Improved strength and durability: The precise alignment of the carbon fibers along the load lines of the rim results in superior structural integrity and durability. Carbon rims with fiber reinforcement are more resistant to fractures, cracks and deformations, which increases their service life and reliability.

- Optimized performance: Thanks to the lighter yet stronger construction, vehicles with carbon rims benefit from improved acceleration, braking performance and handling. This is particularly advantageous in demanding driving situations, such as racing or sporty vehicles.

- Customized design options: Tailored Fiber Placement allows carbon rims to be produced in a variety of shapes and designs. From classic spoked wheels to modern, aerodynamic designs, the possibilities are almost limitless.

Read on and find out more about:

- Fiber preforms

- Reinforcement structures

- Further processing by means of thermosetting

- and thermoplastic processes

Further contributions

Fiber preforms for carbon ship propellers

✓ Are you a manufacturer of ship propellers or boat propellers? ✓ Are you looking for lightweight, high-strength, corrosion-resistant carbon propellers with an optimized and complex design? ✓ Are you looking for a supplier or manufacturer of carbon fiber reinforced boat propellers which can develop complex geometries with you and produce them cost-effectively? Then read on!

Fiber preforms with carbon for UAVs and drones for industry

✓ Are you a manufacturer of innovative UAVs (unmanned aerial vehicles) for industry or the military?

✓ Do you want to make your drone lighter, more robust, more maneuverable or more durable?

✓ Are you looking for a supplier or manufacturer who will work with you to develop and cost-effectively manufacture a customized reinforcement for various parts of your UAV?

Then read on!

High-performance preforms for carbon pole caps for hydrogen tanks

✓ Are you a manufacturer of hydrogen tanks or carbon pole caps for hydrogen tanks?

✓ Do you need lightweight, pressure-resistant, corrosion-resistant and safe preforms for further processing in your pole caps?

✓ Are you looking for a supplier or manufacturer who can produce preforms for your pole caps cost-effectively using the TFP process?

Then read on!