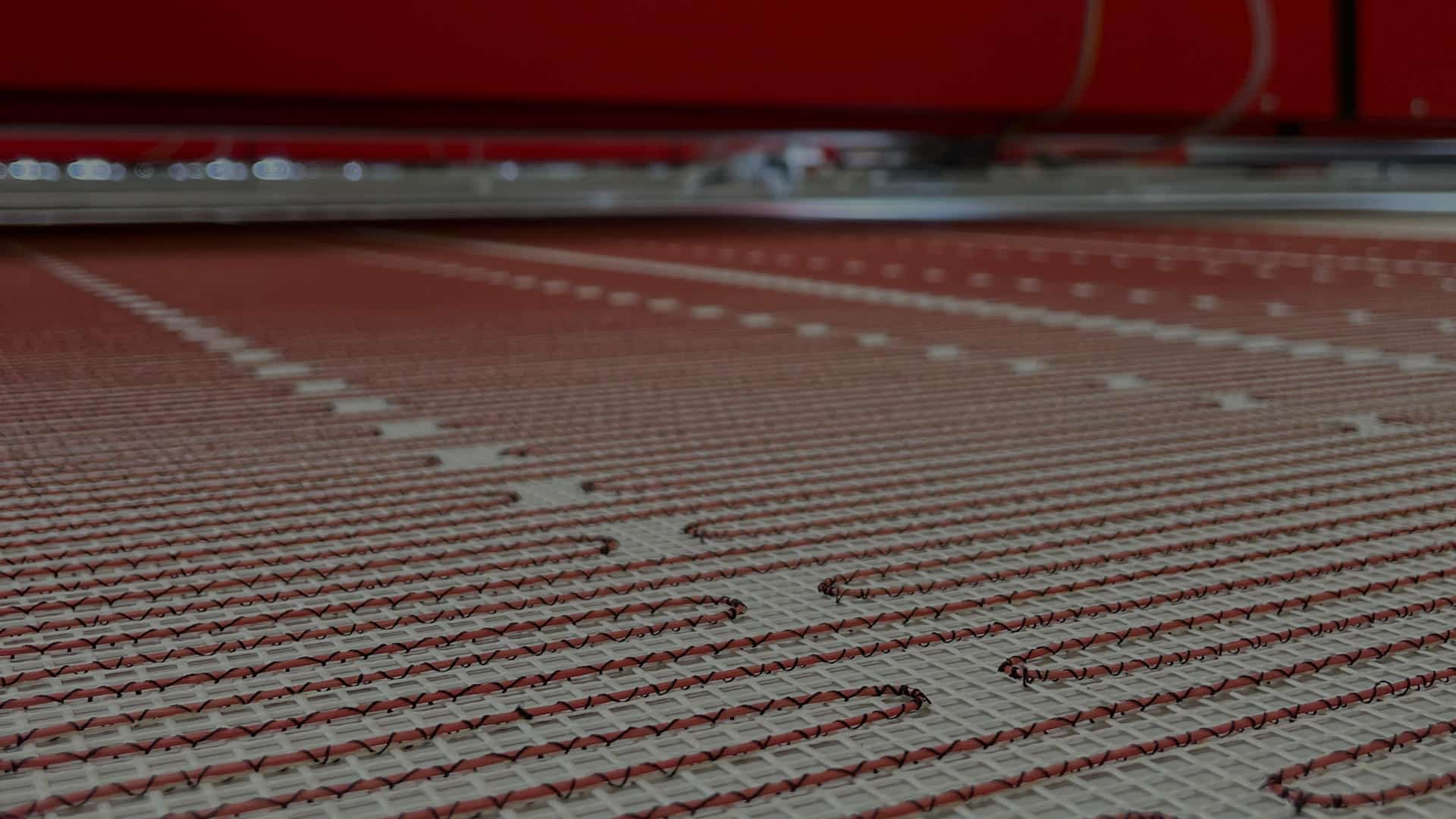

Cost-effective heat mats for mattress heating in series production

✓ Are you a manufacturer of fan components or fans for heat pumps? ✓ Are you faced with the challenge of keeping your fans or ventilators ice-free (anti-icing)? ✓ Are you looking for a cost-effective alternative to the silicone heating mat you have been using up to now? Then read on!