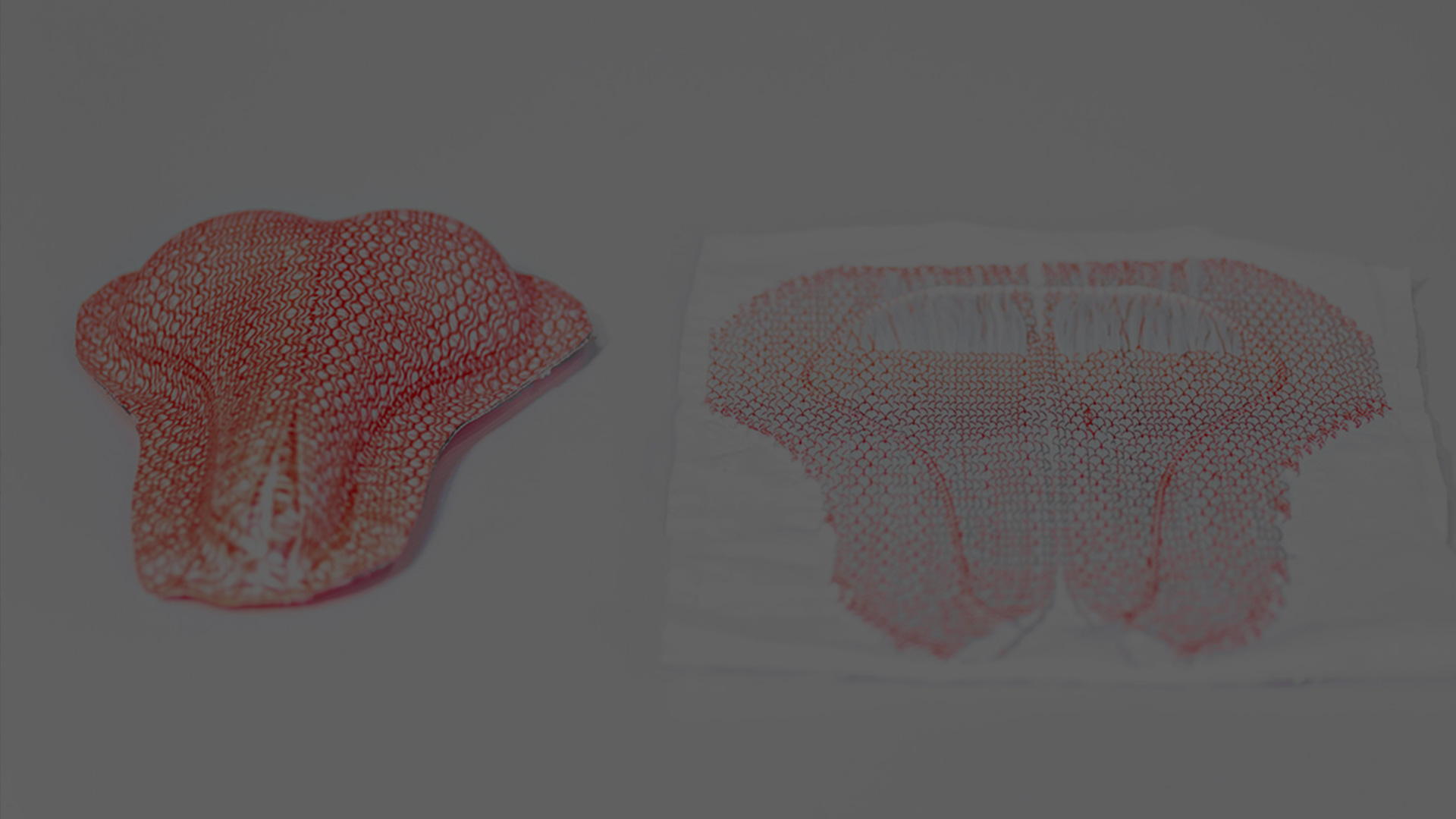

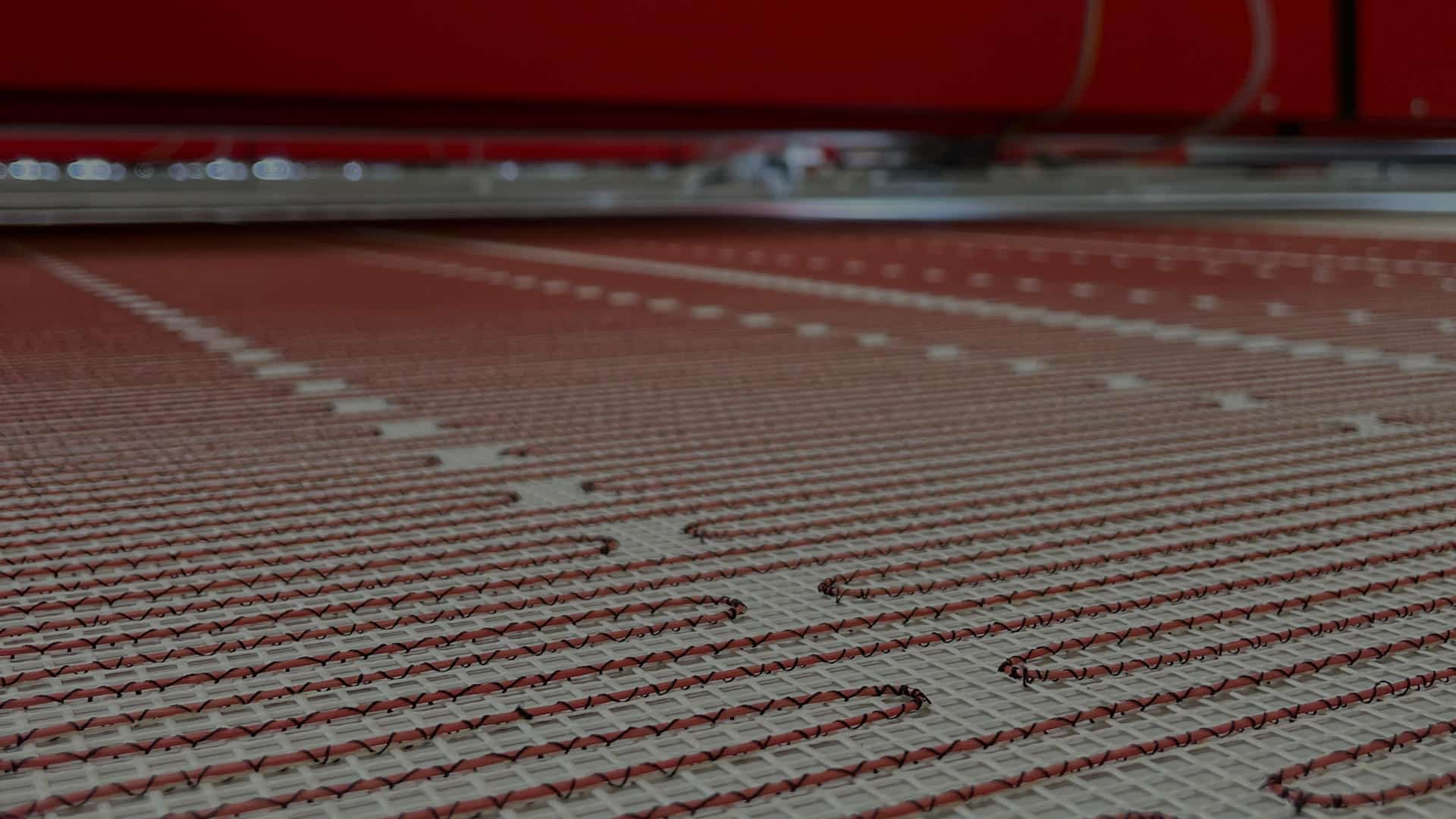

Fiber preforms for carbon ship propellers

✓ Are you a manufacturer of ship propellers or boat propellers? ✓ Are you looking for lightweight, high-strength, corrosion-resistant carbon propellers with an optimized and complex design? ✓ Are you looking for a supplier or manufacturer of carbon fiber reinforced boat propellers which can develop complex geometries with you and produce them cost-effectively? Then read on!